Product Center

Location:Home - Products

Liquid Turbine Flowmeter

The liquid turbine flowmeter is a speed-type instrument, which has the advantages of simple structure, small volume, high accuracy, sensitive reaction and convenient installation and maintenance. It is used for measuring volume flow and accumulation of low viscosity, non-corrosive and clean liquids in closed pipes. If it is matched with the display instrument with special functions, it can also carry out quantitative control, over-limit alarm and so on. It is an ideal instrument for flow measurement and energy saving. It can be widely used in petroleum, chemical industry, metallurgy, organic liquid, inorganic liquid, liquefied gas, urban gas pipe network, pharmaceutical, food, paper making and other industries.

Product Details

Product Overview

The liquid turbine flowmeter is a speed-type instrument, which has the advantages of simple structure, small volume, high accuracy, sensitive reaction and convenient installation and maintenance. It is used for measuring volume flow and accumulation of low viscosity, non-corrosive and clean liquids in closed pipes. If it is matched with the display instrument with special functions, it can also carry out quantitative control, over-limit alarm and so on. It is an ideal instrument for flow measurement and energy saving.

It can be widely used in petroleum, chemical industry, metallurgy, organic liquid, inorganic liquid, liquefied gas, urban gas pipe network, pharmaceutical, food, paper making and other industries.

Product Characteristics

1. High precision, generally up to±1%R, ±0.5%R, and high precision type up to±0.2%R;

2. It has good repeatability and short-term repeatability can reach 0.05% -0.2%. It is due to good repeatability, normal calibration or online calibration can get extremely high accuracy, which is the preferred flowmeter in trade settlement;

3. It outputs a 4-20mA signal and it can be connected with DCS to achieve intelligent control;

4. It outputs pulse frequency signal, and it is suitable for total measurement and connection with the computer, without zero drift and strong anti-interference ability;

5. Original pulse frequency range (10Hz-1.5KHz), with strong signal resolution;

6. The range ratio is wide and the maximum range ratio reaches 1:20;

7. Compact and light structure, convenient installation and maintenance and large circulation capacity;

8. It is applicable to high pressure measurement and we do not have to open a hole on the sensor meter body. It is easy to make high pressure type instruments.

Operational Principle

shows a brief diagram of the liquid turbine flowsensor structure. It is shown from the figure, when the measured liquid flows through the sensor, the impeller is rotated by the liquid. Its rotational speed is proportional to the pipeline average flow speed and the rotation of the impeller periodically changes the magnetoresistance value of the magnetoelectric converter. The magnetic flux in the detection coil changes periodically, producing a periodic induction potential, that is, the electric pulse signal and it is sent to the display instrument after amplification.

Technical Parameter(s)

Measured medium | No impurities, low viscosity, no strong corrosive liquid | ||||

Instrument caliber and connection mode | Thread connection for 4, 6, 10, 15, 20, 25, 32 and 40 Integrated flange or clamping flange connection for (15, 20, 25, 32, 40) 50, 65, 80, 100, 125, 150, 200 | ||||

Accuracy grade | Pipe-segment type: 1.5%, 1%, 0.5%, 0.2% (specially made) | ||||

Range ratio | 1:10-1:20 | ||||

Verification conditions | Verification device | Liquid flow verification device based on master meter method | |||

Liquid flow verification device based on static mass method | |||||

Ambient conditions | Ambient temperature | 20 | |||

Relative humidity | 65% | ||||

Verification conditions | Medium temperature | T1(General, standard) | -20℃~+80℃ | ||

T2(high-temperature type, custom-made) | -20℃~+120℃ | ||||

T2(high-temperature type, custom-made) | -20℃~+150℃ | ||||

Ambient temperature | -20℃~+60℃ | Relative humidity | 5%-90% | ||

Atmospheric pressure | 86KPa~106KPa | ||||

Installation

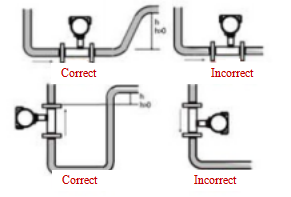

Installation mode of pipe-segment type liquid turbine flowmeter

|

|

Dimension Drawing for DN15-DN200 Flange Connection Type Intelligent Electronic Water Meter Sensor | Dimension Drawing for DN4-DN200 Clamping Connection Type Intelligent Electronic Water Meter Sensor |

|

|

Dimension Drawing for DN4-DN10 Thread Connection Type Intelligent Electronic Water Meter Sensor (including straight pipe section) | Dimension Drawing for DN15-DN50 Thread Connection Type Intelligent Electronic Water Meter Sensor (excluding straight pipe section) |

Installation Precautions

Installation conditions and location

(1) The pipe must be fully filled with liquid. It is important to keep the pipe completely full of liquid at any time, otherwise the flow display will be affected and it may cause measurement errors.

(2) Avoid air bubbles. If there are air bubbles entering the measurement pipe, the flow display may be affected and it may lead to the measurement errors.

6.2.2 Installation Site and Requirements

Installation Site and Requirements

(1) Sensors shall be installed in a place for easy maintenance, no vibration, strong electromagnetic interference and thermal radiation.

(2) Horizontal sensor installation requires that the pipeline shall not be visually tilted (generally within 5°), and the vertical deviation of vertical installation sensor pipeline shall be less than 5°. In places that cannot stop flow, bypass pipe and reliable stop valve should be installed (see above) to ensure no leakage.

(3) Connect a section of short pipe to replace the sensor at the position of the newly laid pipe to install the sensor. After the "pigging" is completed, confirm that the pipeline is cleaned and then formally connect the sensor.

(4) If the fluid contains impurities, the filter shall be installed upstream of the sensor and the pipe shall be regularly cleaned up; if the measured liquid contains gas, the silencer shall be installed on the upstream side of the sensor. The drain outlets and air outlets of filters and silencers shall lead to safe places.

(5) When the sensor is installed outdoors, measures should be taken to prevent direct sunlight and prevent rain.

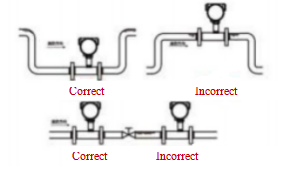

Intelligent liquid turbine flowmeter for straight pipe section length is sensitive to flow velocity distribution distortion and rotation flow in the pipeline, and the liquid flowing into the sensor shall be the fully developed turbulence. Therefore, it is required to provide the necessary straight pipe section or rectifier according to the baffle type in the upstream side of sensor, and the straight pipe section lengths for inlet and outlet sections are required.

Baffle type for inlet section | Installation conditions | Baffle type for inlet section | Installation conditions | ||

Inlet section | Outlet section | Inlet section | Outlet section | ||

Ordinary circumstances | Flow direction

| 90-degree bend | Flow direction

| ||

Two 90-degree bends in the same plane | Flow direction

| Two 90-degree bends in different planes | Flow direction

| ||

Pipe-contracting | Flow direction

| Pipe-expanding | Flow direction

| ||

Full-open valve | Flow direction

| Semi-open valve | Flow direction

| ||

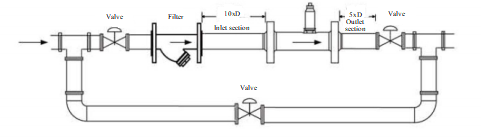

Examples for installation dimensions

The dimension shown in Table 7 is the minimum required straight pipe section installation length for accuracy, and it is improved if the length of the straight pipe section is doubled.

Upstream: the allowable minimum straight pipe section length is at least 10 times of the pipe diameter.

For example, the ABLWGY-50, upstream straight pipe section length is at least 500mm and the desired upstream straight section length shall be 1,000mm.

Downstream: the minimum allowable straight pipe segment length is at least 5 times of the pipe diameter.

For example, the ABLWGY-50, downstream straight pipe segment length is at least 250mm. The desired length of the downstream straight pipe segment shall be 500mm.

涡街流量计

涡街流量计主要用于管道介质流体的流量测量,如气体、液体、蒸汽等多种介质,在测量工况体积流量时几乎不受流体密度、压力、温度、粘度等参数的影响。涡街流量计采用压电应力式传感器,可靠性高,使用寿命长,可在(-20-350)℃的工作温度范围内工作。有模拟标准信号,也有数字脉冲信号输出,容易与计算机等数字系统配套使用,是一种比较先进、理想的测量仪器。

View Products

超声波流量计

LCT超声流量计采用时差法计算流量,利用先进的微处理数字技术,特别适用于区域供热,热源厂,换热站,暖通空调(空调制冷设备)、自来水等液体的流量测量。 LCT超声流量计包括流量传感器和流量转换器;流量传感器采用多声道超声波,分别测量管道内不同流体层的介质流速,由软件自动补偿计算管段内介质的截面流速。流量转换器采用高速混合信号处理CPU,配备高精度

View Products

电磁流量计

ABDT-LD系列智能电磁流量计是一种比较成熟的液体测量仪表,适用于测量封闭管道中导电液体(电导率≥5µs/cm)和浆液的体积流量,适用于各种酸碱盐溶液、清水、海水、污水、泥浆、纸浆、矿浆、低电导率液体等。广泛应用于工业生产过程控制、能源计量、环境保护、污水处理等领域。

View Products

FC6000智能流量积算仪

AOBO-FC6000智能流量积算仪是全新平台打造的智能型中英文菜单组态的通用型流量计算机,以更快的计算速度、更低的功耗、更可靠的工作性能来完成对蒸汽、气体、液体的流量计量演算功能,能实时在线对流体的温度、压力进行补偿,能同时接收流量、温度、压力等信号,信号可以是频率、电流、差压、电阻等类型,信号处理采用无开关触点、无电位器可调部件技术,使得计量

View Products