Product Center

Location:Home - Products

ABDT-RM Remote Meter Reading System

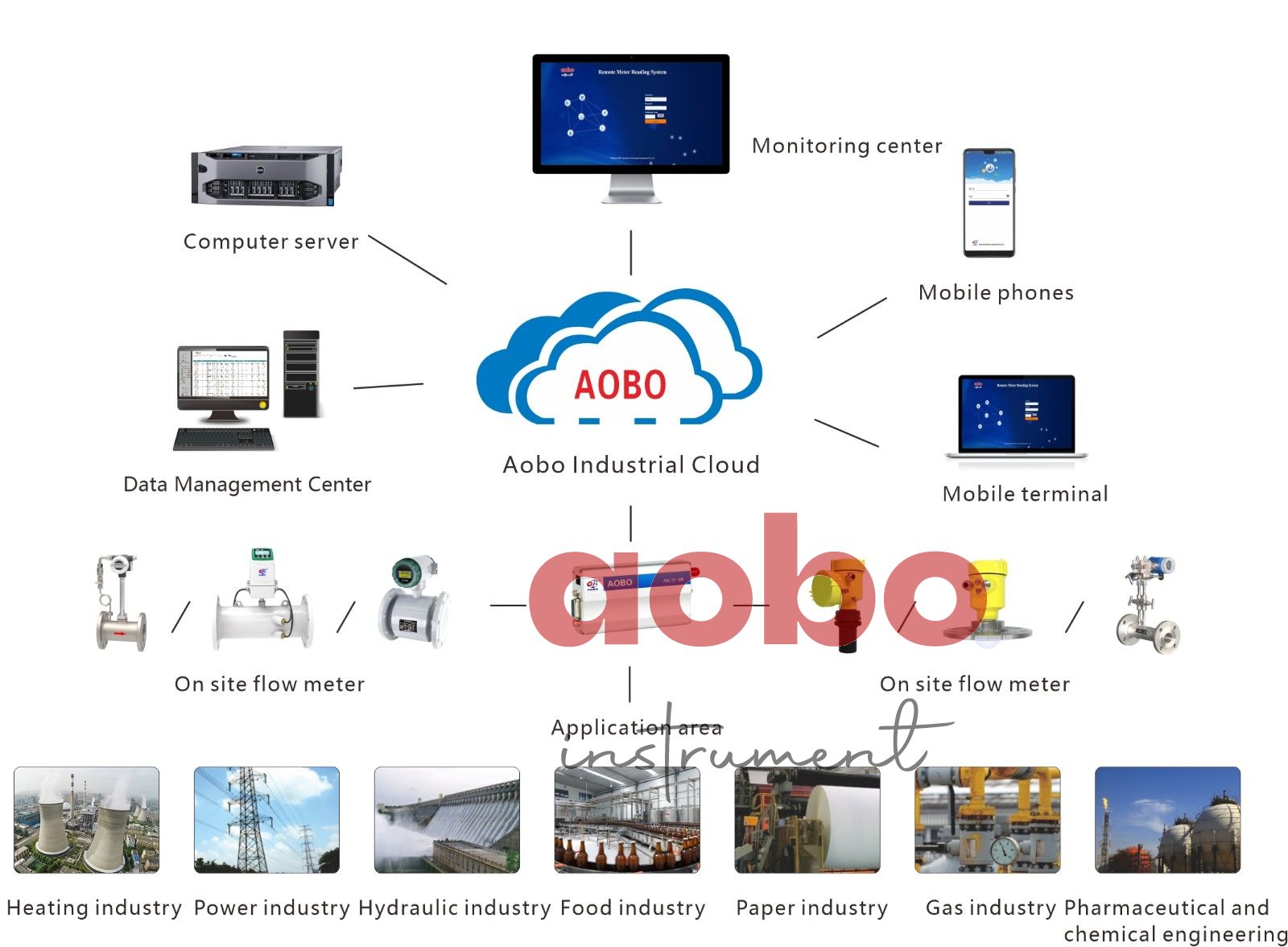

In order to meet the various needs of users for measurement and energy conservation, our company has independently developed an intelligent remote meter reading system (energy management) that adapts to various user needs. In terms of software and hardware, it adopts standardized and reliable design, and meets national standards. Widely used in fields such as thermoelectric, chemical, natural gas, papermaking, pharmaceuticals, biotechnology, urban heating, etc. After several years of practical operation, it has been widely recognized by customers. The software and hardware of the system adopt standardized, reliable design, comply with national standards, and adapt to the relevant requirements of the energy industry. The software and hardware design of the remote meter reading system follows the principles of security, reliability, openness, maintainability, and scalability: it adopts modular standardized design, conforms to national standards, and adapts to the collection, analysis, and query of water, electricity, steam and other measurement instrument data by major enterprises, providing strong data support for refined management of enterprises.

Product Details

Overview

In order to meet the various needs of users for metering and energy saving, our company independently developed a (energy management) intelligent remote meter reading system that adapts to various user needs. It adopts standardized, reliable design in software and hardware and conforms to national standards. It is widely used in thermal power, chemical industry, natural gas, papermaking, pharmacy, biotechnology, urban heating and other fields. After several years of actual operation, it has been widely recognized by customers. The software and hardware of the system adopt standardized and reliable design, conform to national standards, and adapt to the relevant requirements of the energy industry. The software and hardware design of the remote meter reading system follows the principles of safety, reliability, openness, maintainability and scalability: adopts modular standardized design, conforms to national standards, and adapts to major enterprises' measuring instruments for water, electricity, steam, etc. Data collection, analysis and query, etc., provide strong data support for the refined management of enterprises.

Hardware: The core module produced with international advanced technology is used to achieve permanent and stable online automatic search of the network;

System introduction

GPRS is the English abbreviation for General Packet Radio Service, which is developed on existing systems to provide GSM users with packet data services. It is particularly suitable for energy management related requirements such as remote meter reading and data transmission of monitoring and control systems in thermal power, natural gas, tap water, electric power, and other industries.

Through the comparative analysis of technology progressiveness, system compatibility, expansibility, network coverage, enterprise investment scale and benefits, the adoption of China Mobile's GPRS network as the communication transmission medium can improve the timeliness, reliability, accuracy of enterprise measurement information and realize the informatization of enterprise production management. GPRS wireless internet remote meter reading is the most advanced, reliable, and ideal choice for enterprises.

The GPRS energy management wireless remote meter reading system developed by Weifang Aobo Instrument Co., Ltd. enables user terminals to automatically connect to the network when powered on, always online, automatically send real-time data of on-site operating conditions, and can respond to queries and control instructions from the central computer in a timely manner. The central computer is equipped with a network database and powerful data processing software, enabling data sharing between local and wide area networks and mobile office work for key leaders. It overcomes the shortcomings of all previous remote meter reading systems and integrates all the advantages. It is now the most advanced remote meter reading system.

System Composition

(1) Terminal equipment:

Measuring instrument: equipped with standard ModBus communication protocol (or other communication protocols) and 485 communication interface, such as MC51 series totalizer, electricity meter, etc;

Communications equipment: industrial grade GPRS wireless data transmission module; Based on mobile GPRS digital communication network, seamless coverage is achieved. Support static IP address and dynamic domain name resolution; Standard RS232 or RS485 interface, compatible with multiple technical protocols.

(2) Data center server:

A data server and a local area network are established within the company, which are connected to INTERNET. The server has a fixed IP address for receiving, sending, saving data, and realizing wide area network sharing of data. Access the server through the internal LAN for data query and backup.

Remote monitoring software

The data center monitoring system is designed with a B/S structure, featuring stable system stability and data security. The software is developed based on the. NET platform using common programming languages such as C # and JS. The database uses the network database SQL SERVER, which has good versatility and strong pertinence. It can analyze, process, and save real-time data transmitted from user instruments, generate various reports and curves, and produce various graphics, thereby achieving remote meter reading of the entire system, Real-time monitoring and automated management functions. The software has the advantages of beautiful and concise interface, practical functions, and easy to understand operation.

GPRS energy management remote meter reading system has been successfully applied in the following industries: thermoelectricity, chemical industry, papermaking, biotechnology, urban heating, etc. It mainly collects data from metering instruments and electronic scales for media such as steam, gas, water, electricity, and finished products, providing enterprises with the following data: cumulative amount, instantaneous amount, pressure, temperature, density, frequency (or differential pressure signal), working mode, instrument coefficient Number and time of power outages, etc.

The transmission parameters of the electricity meter mainly include: active power, reactive power, ABC three-phase voltage, ABC three-phase current, active power, reactive power, power factor, etc.

The main transmission parameters of the natural gas instrument include: standard cumulative, standard instantaneous, work cumulative, work instantaneous, total gas purchase, gas purchase margin, frequency, pressure, temperature, battery voltage, etc.

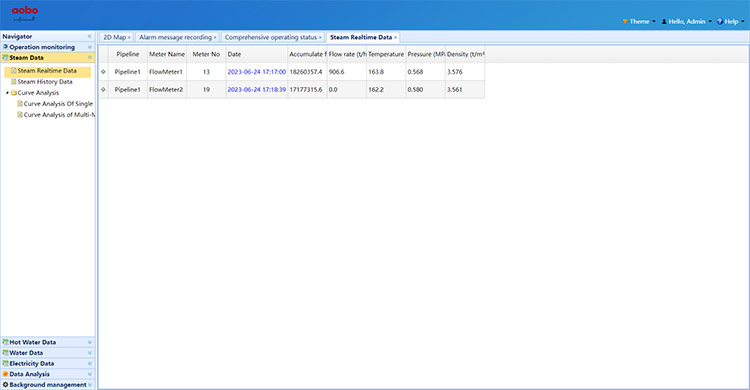

Transmission parameters of vortex street, ultrasonic, and electromagnetic flow meters include instantaneous flow, cumulative flow, pressure, temperature, forward accumulation, and reverse accumulation.

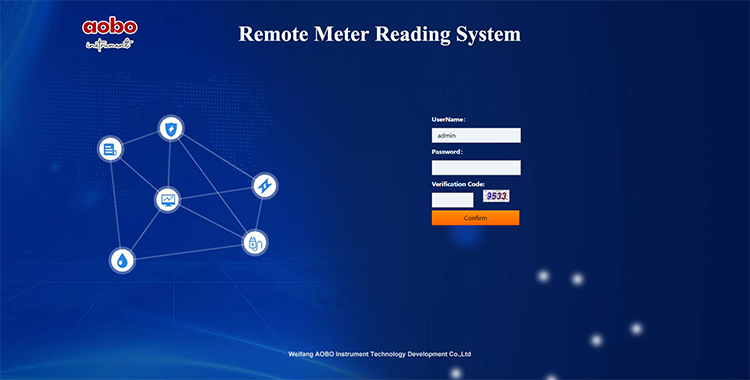

First, log in to the system: System operation and shutdown must be verified by legal permissions, including verification of user names and corresponding passwords. This effectively protects the security of system data. login interface:

Open the user interface and provide a friendly Chinese operation screen. The overall feeling is clear and pleasing to the eye. The control panel adopts a tree structure with strong logic. Each page is equipped with a return and home button, which is convenient and quick.

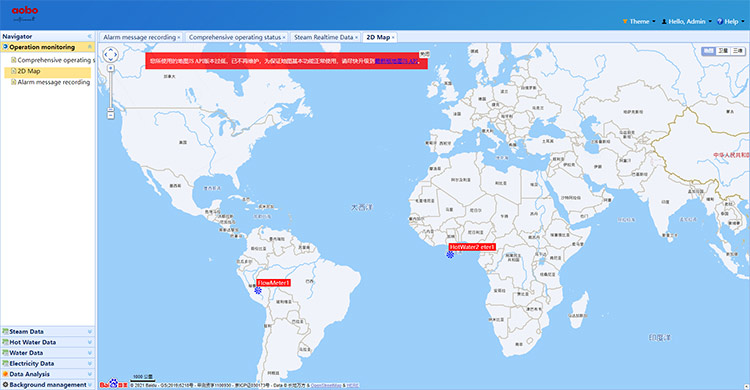

(1) Pipe network map: The pipe network map in the user management interface has two methods: user-defined pipe network map and two-dimensional map. The interface can be arbitrarily scaled. The user can click to display the user's basic working condition data and status indicator light, and directly click the mouse to obtain instrument data and user real-time and historical curves, and can set parameters for the user. The steam pipe network diagram is shown below:

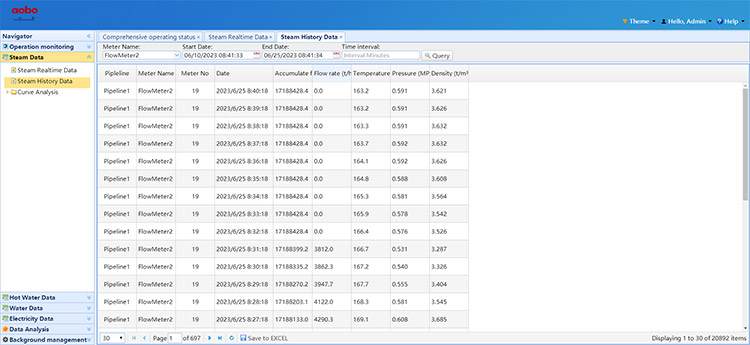

(2)Real time data: including user dynamic data and historical data curves. Click the corresponding command to obtain the flow rate, pressure, temperature, frequency, density, and other operating conditions or historical data and curves displayed by all user meters, and real-time refresh the display system to display all user real-time operating conditions data received.

(3) Data query: The formed historical database can facilitate classified and combined queries. Provide historical data query on the year, month, and day of all users. All data and reports can be saved, exported, and printed. All users can be directly selected from the user drop-down list, and the time period can also be arbitrarily selected.

(4) Comprehensive Report: You can query the data parameters of all users for any historical time period, and save, export, and print them. This interface displays all user information. The time period includes the month, month, and day, which can be arbitrarily selected. You can display data and charts in two ways. You can generate reports for various single media, including daily reports, monthly reports, ten-day reports, and annual reports.

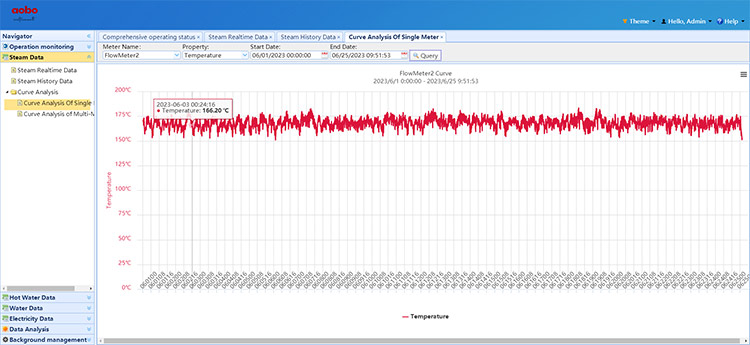

(5) Curve analysis: You can query instantaneous quantity curve, cumulative quantity curve, pressure curve, and temperature curve; The time period, including the month, month, and day, can be arbitrarily selected, and multiple devices can be selected at the same time to facilitate data analysis and can be saved, exported, and printed.

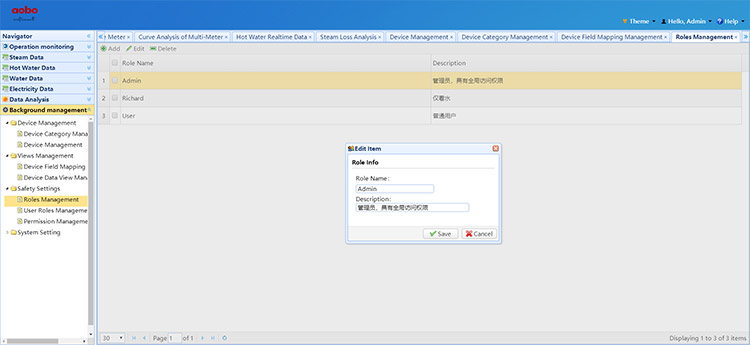

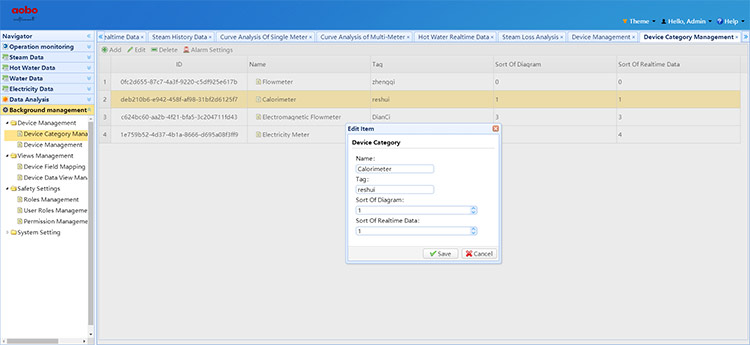

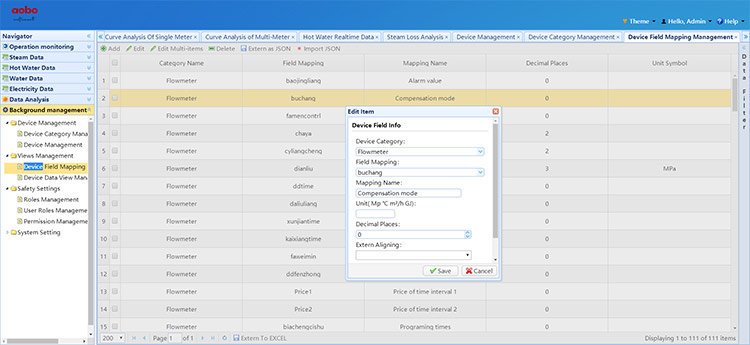

(6) Background management: including device management, view management, security settings, and system settings. In device management, users can be added indefinitely and alarm parameters can be set.

In view management, you can set parameters displayed in data center and curve analysis.

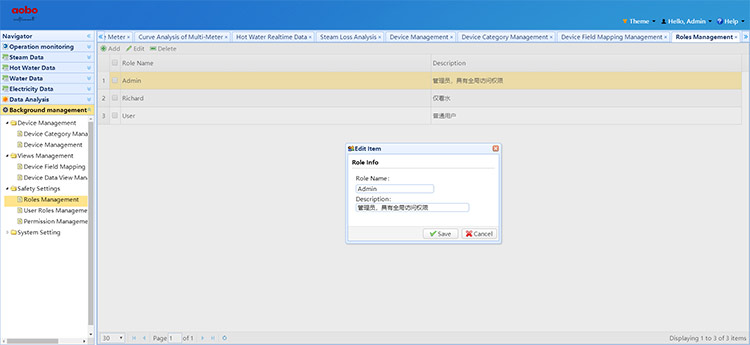

Role management, user role management, and permission management can be set in security management; According to permission management, it can be set as super administrator, administrator, and general user; A super administrator has all management permissions, and administrators and ordinary users can only perform their own binding permissions.

(7) Work indicator light: The function of the work indicator light is clearly described on the panel, that is, when the instrument is normal, abnormal (such as power failure of the instrument), out of limit alarm, and not connected, it is indicated with different color indicator lights.

(8) Various reports can be customized according to user requirements.

Data security

The system adopts a B/S structure, and the administrator of the system has the highest permissions. Other users need to open their permissions for using data. Low privilege users can only view the assigned privilege data and reports, and cannot access data beyond their authority, nor can they access data with each other.