Product Center

Location:Home - Products

Flange-Display Vortex Flowmeter

Vortex flow meters are mainly used for measuring the flow rate of pipeline medium fluids, such as gases, liquids, steam, and other media. When measuring the volumetric flow rate under operating conditions, they are almost unaffected by parameters such as fluid density, pressure, temperature, and viscosity. The vortex flowmeter adopts a piezoelectric stress sensor with high reliability and long service life, and can operate within the operating temperature range of (-20~420) ℃. There are analog standard signals and digital pulse signal outputs, which are easy to use in conjunction with digital systems such as computers. It is a relatively advanced and ideal measuring instrument.

Product Details

Overview

The LUGB series vortex flow sensor is a fluid vibration flow detection instrument made of piezoelectric ceramics as the sensitive elements according to the principle of Karman vortex and uses the stress detection method.

The sensor is simple and motion-free. It has high stability and reliability. It has unique medium versatility and its instrument coefficient is universal for different medium.

The flow measurement system composed of the sensor is simple, easy to install and maintain, small pressure loss, large measurement range and good economy. In the environment with inflammability and explosive gas, explosion-proof products should be selected, explosion-proof grade: ExdIICT6Gb, explosion-proof number: SYEx19.12246.

The LUGB series of vortex flow sensors produced by our company strictly implement national and industrial standards, and conduct real flow calibration stage by stage. The core component —— detection probe adopts seismic design, which effectively improves the seismic performance; the test part external sensor, sensitive element on the surface, and the temperature of measurable fluid medium reaches 420℃.

LUGB series vortex flowmeters are widely used in petroleum, chemical, metallurgy, thermal, textile, paper and other industries, suitable for the measurement and detection control of over thermal steam, saturated steam, compressed air and general gas (oxygen, nitrogen, hydrogen, natural gas, gas, etc.), liquid (water, gasoline, alcohol, benzene, etc.).

Working Principle

The vortex flowmeter is a fluid vibration instrument developed by the principle of "Karman vortex". A non-fluid vortex generator is placed in the fluid, which alternately separates on the sides of the vortex generator, releasing two columns of regular staggered arranged vortices.

Within a certain flow velocity range, the separation frequency of the vortices is proportional to the flow rate, which is detected by the piezoelectric ceramic detection element. It is transformed into alternating electric signals. After amplifying, filtering and shaping, it outputs a voltage pulse signal or (4-20) mA standard current signal proportional to the flow rate.

Product Characteristics

1. Wide measurement range;

2. High measurement accuracy;

3. Simple and firm structure, no moving parts, and long service life;

4. Simple maintenance, easy to install, small workload and low cost;

5. It has a wide range of applications. The flow of steam, gas and liquid can be measured;

6. It has a small pressure loss, high accuracy, good repeatability and good long-term working stability;

7. The output frequency signal is not affected by the fluid temperature, pressure, viscosity, density, etc.

Technical Parameter(s)

Nominal general diameter: DN15~DN800;

Nominal pressure: 1.6MPa, 2.5MPa, 4.0MPa, Other ranges can be customized;

Measurement medium(s): liquid, gas, steam or other single phase or considered single phase mediums;

Medium temperature: (-20~420) ℃;

Accuracy: grade 1.0 and grade 1.5;

Range degree: 1:10~1:15; intelligent type: above 1:15;

Pressure loss factor: Cd=2.4;

Power supply: DC 24V, DC 12V, DC 3.6V lithium battery;

Case material: 1Cr18Ni9Ti, and other materials are required for the strong corrosion mediums;

Environmental conditions: (-40~55) ℃ [Field display type(-20~55) ℃], humidity of (5~90)%RH, atmospheric pressure of (8~106) KPa, explosion-proof type (-20~40) ℃;

Protection grade: IP65 IP68;

Explosion-proof grade: ExdIICT6Gb, explosion-proof number: SYEx19.12246.

Installation Requirements

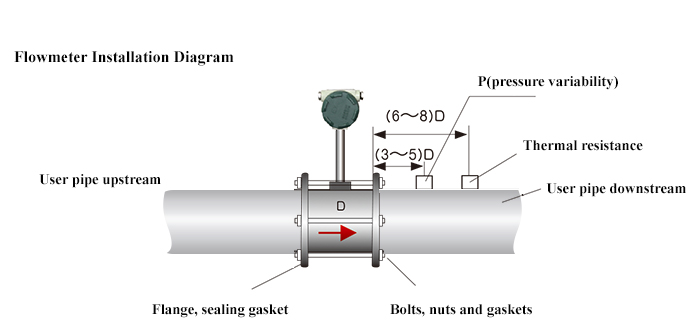

(1) The upstream and downstream of the vortex flow sensor shall have a long enough straight pipe section (D is the sensor diameter) as required in the figure below.

Concentric contraction, full open valve Concentric pipe-expanding

Two 90-degree bends in different planes Two 90-degree bends in the same plane

A 90-degree bend Adjustment valve semi-open valve (not recommended)

(2) When temperature pressure compensation is required, the pressure and temperature measurement points shall be set at the downstream end surface of the flow sensor (3~5) D and (6~8) D respectively, the pressure hole diameter (6~12) mm. The root of the pressure-taking short pipe is flush with the inner wall of the pipeline and shall not go deep into the inner wall of the pipeline. Insert the front end of the thermal resistance sheath into the center of the pipe as far as possible.

Sensor Installation Diagram

(3) The inner diameter of upstream and downstream piping shall be the sensor diameter. If it is not, pipes that are slightly larger than the sensor diameter shall be used, The error shall be ≤ + 3%, and do not exceed 5mm; piping shall be concentric with the sensor, axiality<0.05D; gasket shall not protrude into the pipe and the inner diameter shall be larger than the sensor diameter (1-2) mm.

(4) To avoid the influence of pipeline vibration, it should be considered to add fixed support about 2D upstream of the flowmeter or add elastic hose on the premise of satisfying the length requirement of straight pipe section before adding support.

(5) The vortex flow sensor shall be installed in a safe place for installation, commissioning, overhaul and good environment. Enough operation space shall be left around. An operating platform shall be provided when installation at high altitude. Avoid installation in strong electromagnetic field, strong mechanical vibration environment and the environment of temperature and humidity not consistent with the service conditions.

(6) The vortex flow sensor can be installed in the horizontal, vertical or inclined pipe, but the specific position shall be selected to ensure that the pipe is full and avoid the influence of bubbles when measuring liquid; the influence of liquid accumulation must be avoided when measuring gas (steam).

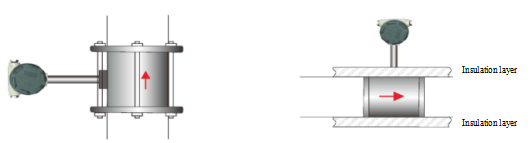

Liquid measurement

When measuring the liquid, the vortex flow sensor shall be installed at the lower part of the pipeline.

Gas measurement

When measuring gas (steam) flow, the vortex flow sensor shall be installed in the higher part of the pipeline.

The vortex flow sensor is installed in the vertical pipeline. When measuring the gas (steam) flow, the flow direction of the medium is not limited; when measuring the liquid flow, the flow direction should be from bottom to top.

(7) When the vortex flow sensor is installed in horizontal piping, the gauge outfit shall be avoided downward and tilted up 45 degrees.

(8) When installing the insert type vortex flow sensor, ensure that its axis coincides with the pipeline center line and it is perpendicular to the pipeline axis. The insertion depth meets the requirements and the flow direction is correct. The measuring head axis is parallel to the pipeline axis and the angle error is less than 7°. After the flow direction is adjusted, it should be locked to avoid rotation.

(9) Before welding, the vortex flow sensor shall be removed. Welding with meter is prohibited; the flow sensor connecting rod cannot be insulated during pipeline insulation.

(10) If necessary, the vortex flowmeter shall be reliably grounded, with a grounding resistance≤ 10Ω.

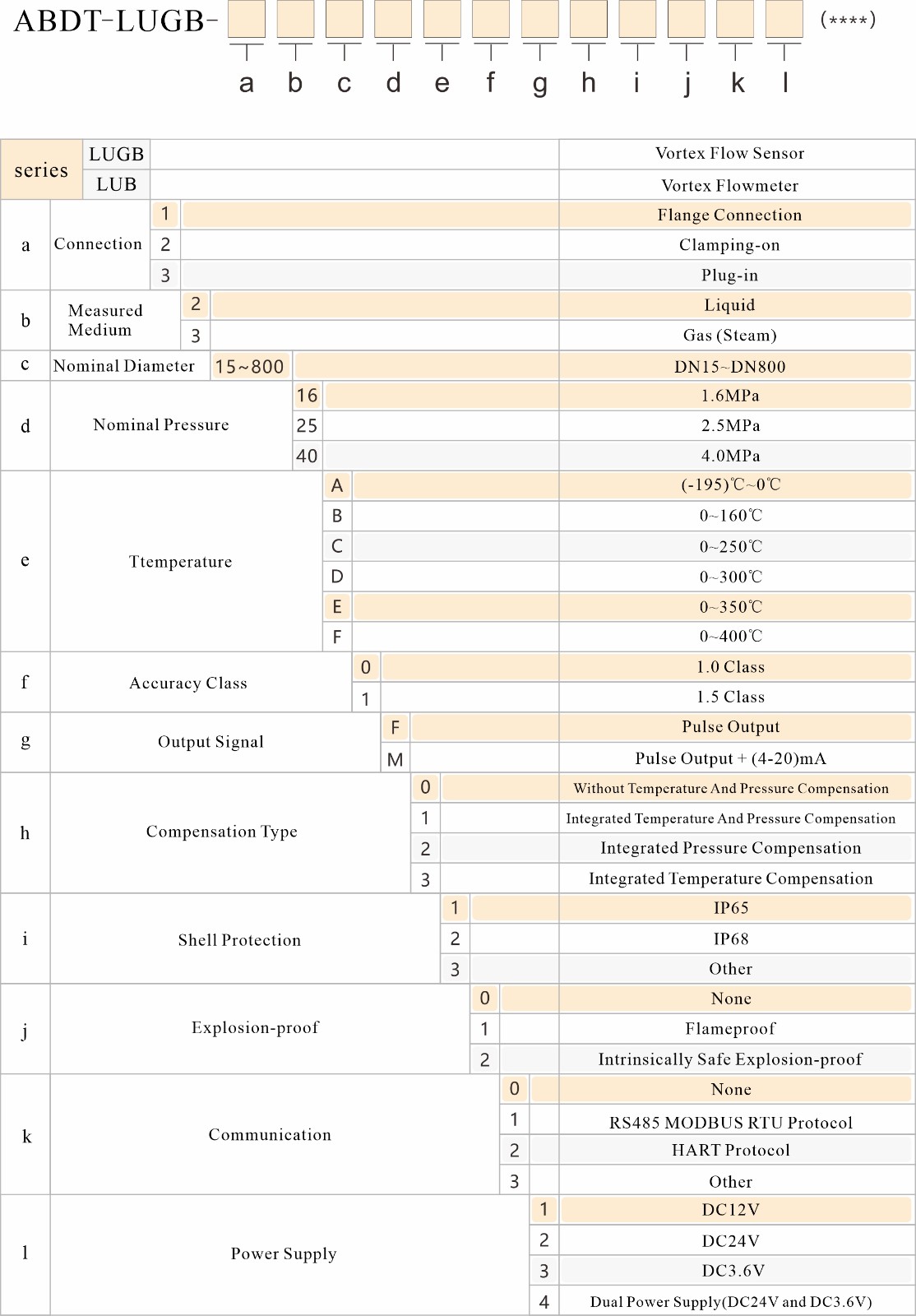

Type Selection

FC6000 intelligent flow totalizer

AOBO-FC6000 intelligent flow totalizer is a universal flow computer with intelligent Chinese and English menu configuration built on a brand new platform. It completes the flow measurement and calculation functions for steam, gas, and liquid with faster calculation speed, lower power consumption, and more reliable working performance. It can compensate for the temperature and pressure of the fluid in real-time online, and can simultaneously receive signals such as flow, temperature, and pressure

View Products

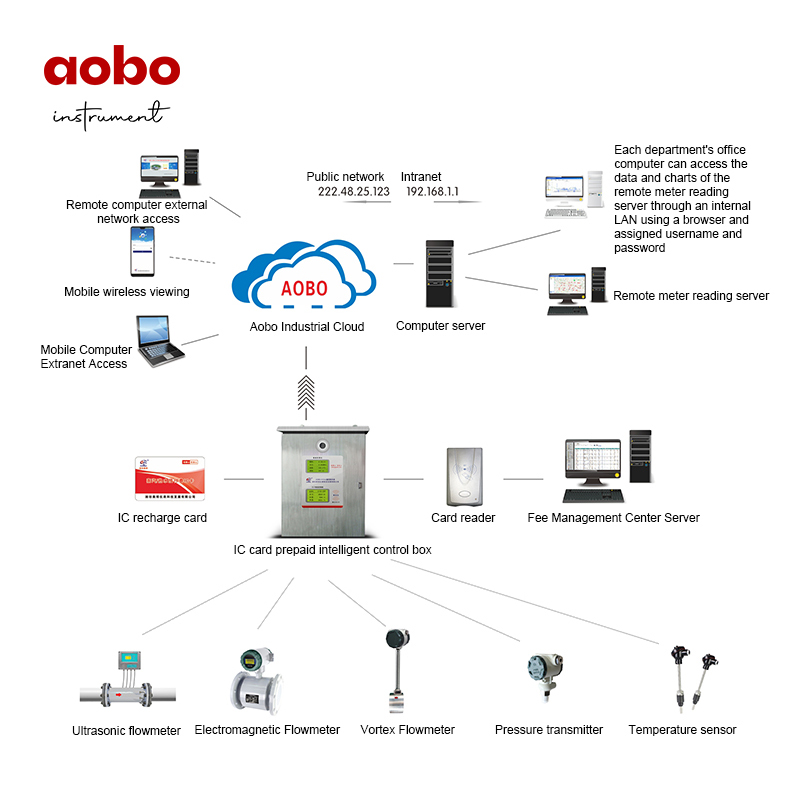

Steam/Hot Water IC Card Prepayment Intelligent Control System

In order to avoid billing disputes between energy supply and demand parties, reduce conflicts, and enable energy consuming units to consume clearly, Weifang Aobo Instrument independently developed and produced an IC card prepayment intelligent measurement and control system in 2008 that integrates early warning, anti-theft, and battery life functions, achieving a "payment before consumption" mode, completely solving the problems of difficult charging, meter reading, and management in thermal pow

View Products

ultrasonic flowmeter

The LCT ultrasonic flow meter uses the time difference method to calculate the flow rate, and utilizes advanced micro processing digital technology. It is particularly suitable for measuring the flow rate of liquids such as regional heating, heat source plants, heat exchange stations, HVAC (air conditioning and refrigeration equipment), and tap water. LCT ultrasonic flow meter includes a flow sensor and a flow converter; The flow sensor adopts multi-channel ultrasound to measure the flow velocit

View Products

Electromagnetic Flowmeter

The ABDT-LD series intelligent electromagnetic flowmeter is a relatively mature liquid measurement instrument, suitable for measuring the volume flow rate of conductive liquids (conductivity ≥ 5 µ s/cm) and slurries in closed pipelines. It is suitable for various acid, alkali, salt solutions, clean water, seawater, sewage, mud, pulp, mineral pulp, low conductivity liquids, etc. Widely used in industrial production process control, energy metering, environmental protection, sewage treatment an

View Products