Product Center

Location:Home - Products

MC51-Y2 Intelligent Flow Totalizer

As a general flow totalizer with 16-bit single chip computer with ultra low power consumption as the core and intelligent Chinese/English menu configuration, MC51-Y2 intelligent flow totalizer can carry out the steam, gas and liquid measurement with faster computing speed, lower power consumption and more reliable performance. It can make real-time online fluid temperature and pressure compensation. It can receive flow, temperature, pressure and other signals at the same time. The signal can be frequency, current, differential pressure, resistance and other types. The technology based on adjustable parts without switch contact and potentiometer is adopted for signal processing, in order to provide more accurate and reliable flow measurement.

Product Details

Overview

As a general flow totalizer with 16-bit single chip computer with ultra low power consumption as the core and intelligent Chinese/English menu configuration, MC51-Y2 intelligent flow totalizer can carry out the steam, gas and liquid measurement with faster computing speed, lower power consumption and more reliable performance. It can make real-time online fluid temperature and pressure compensation. It can receive flow, temperature, pressure and other signals at the same time. The signal can be frequency, current, differential pressure, resistance and other types. The technology based on adjustable parts without switch contact and potentiometer is adopted for signal processing, in order to provide more accurate and reliable flow measurement.

The totalizer adopts Watchdog technology, effectively preventing the totalizer breakdown in the industrial fields.

With the new flash technology, the totalizer data can be saved for more than 10 years after power failure.

With MODBUS communication technology with RS232/485 interface, the totalizer can be networked with various networks or industrial buses to realize remote meter reading.

Technical Index

1. Flow input signal

Frequency signals, such as vortex flowmeter and turbine flowmeter;

(4~20)mA current signals, such as electromagnetic flowmeter and ultrasonic flowmeter; differential pressure signals, such as orifice flowmeter and V-cone flowmeter. Notes: (1) standard of frequency signal: voltage pulse, VLow.≤1V, VHigh≥5V; received frequency range: (0~5000)Hz; (2) (4~20)mA current received for the differential pressure signal (linear signal).

2. Pressure input signal

(4-20) mA current signal

Note: Steam pressure compensation range: saturated steam 0~2.0MPa;

Superheated steam : 0~4.5MPa (common 0~3.0MPa).

3. Temperature input signal

Pt100 platinum resistance;Temperature transmitter signal for (4~20)mA current output.

Note: The steam temperature range:(0~600)℃(Commonly used:0℃~600℃)

4. Accuracy: grade 0.5;

5. Communication function (equipped according to the customer requirements):

RS232 or RS485 interface, standard Modbus protocol.

6. Display function

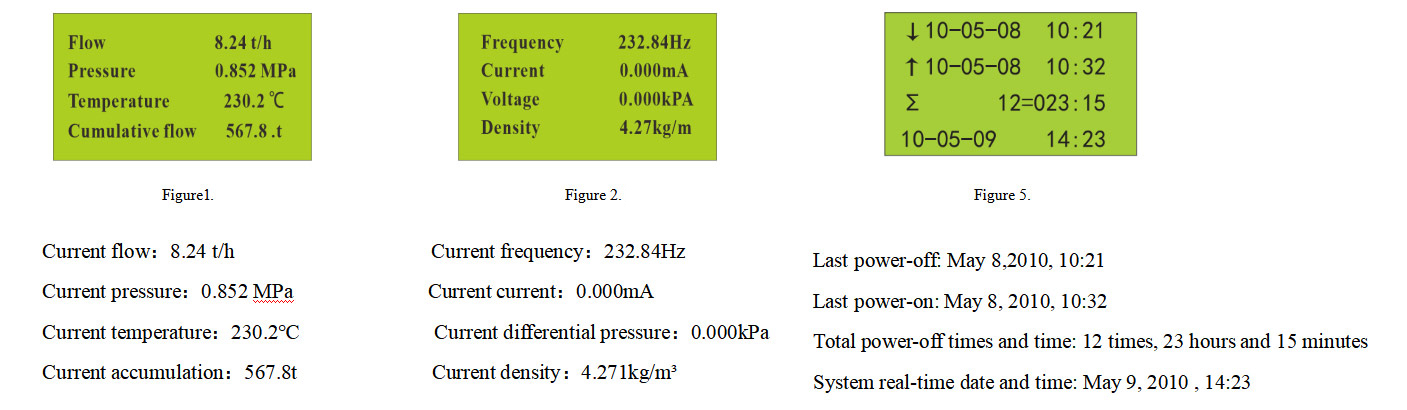

Instantaneous flow, cumulative flow, pressure, temperature,frequency, current, differential pressure, density, number of power loss,record, date,time, the last power loss/power on time,

7. Automatic compensation function

When the temperature and pressure automation compensation mode is selected, the compensation shall be carried out according to the working mode of the saturated steam, if the field temperature is lower than the saturated steam temperature corresponding to the pressure; on the contrary, the compensation shall be carried out according to the superheated steam working mode.

8. Small signal removal function

In the environment with slight vibration or disturbance, removing the interference signal improves the measurement stability of the totalizer.

9. Power-off protection function

The results of the operation and the data set by the user will not be lost during power off and it will be saved for more than 10 years.

10. Working power supply

AC220V±15%, power dissipation<5W.

DC12V±5%,

11. Output power supply

There are two groups. One is 12V/30mA and another is 24V/200mA.

12. Work environment

Temperature: (-10-60)℃, humidity: (5-85)%RH

13. Installation method: horizontal installation

14. Opening size

152±0.5×76±0.5 (W×H, in mm)

15. Outline size

160×80×120 (W×H×D, in mm)

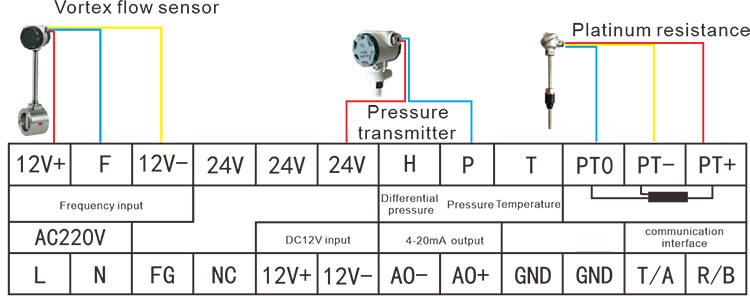

Wiring Diagram

Feed output description: all 12V and GND are the same set of power supply output, and 24V and GND are the same set of power supply output.

Structure

Standard insert type

Display Function

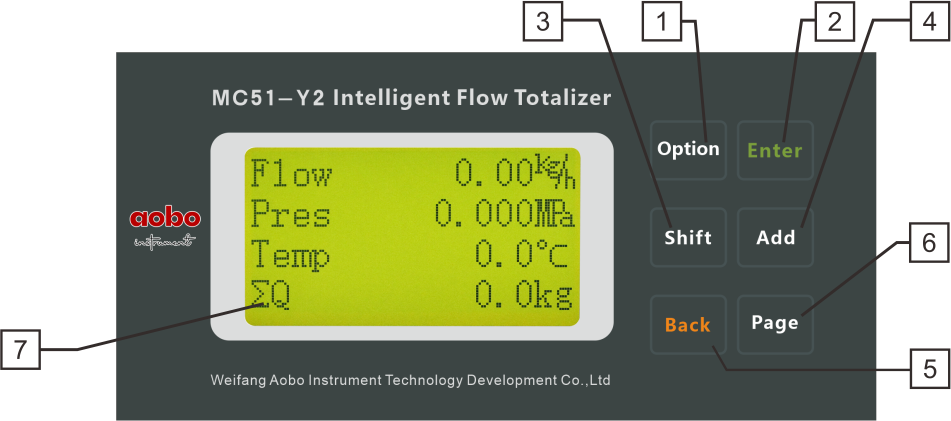

Totalizer panel:

Panel description:

No. | Name | Content |

1 | option key | option key for parameter setting. |

2 | Enter key | Enter totalizer parameter setting; Confirm the set value changed; To enter the current item in changing the set value. |

3 | Shift key | Set the cursor position when changing the set value. |

4 | Add key | Increase number when changing the number; Select the current setting item when changing the set value. |

5 | Back key | Exit the current setting item when changing the set value. |

6 | Page key | Call the display picture when the working conditions are displayed; Change the current setting item when changing the set value. |

7 | Display screen | Display the real-time measured value (fixed display or cycle display); Display the setting parameter(s) in the state of parameter setting. |

Working condition display interface:

Press the “Page ” key to display the desired content. All display pictures can be displayed by the panel keyboard at any time, and which also can be displayed circularly or fixedly through programming. The display pictures of working conditions are as follows: