Product Center

Location:Home - Products

Handhled Ultrasonic Flowmeter

The ABDT-LCT series flow meter incorporates the latest ICs manufactured from the famous semiconductor manufacturers like Philips, Maxim, TI, winbond, and xilinx. The hardware features the ease of operation, high accuracy and outstanding reliability, while the software provides a very user friendly interface and much more functions. It employs a patent balanced lower voltage multi-pulse igniting circuit which increases the anti-interference ability magnificently so that the flowmeter will work properly even in demanding industrial environments such as those with power frequency transverter working nearby.

Product Details

Overview

Welcome to the ABDT-LCT-S series ultrasonic flow meter that has been manufactured with patent technologies and is equipped with more functions and advanced performance than our previous versions.

The advanced circuit design, the integration ofthe latest semiconductors, the user-friendly software interface both in English and Chinese languages and small-sized PCB board, all these features combine to make the ABDT-LCT-S series ultrasonic flow meter the best and the biggest seller on the Chinese market. Moreover, it is gaining more and more recognition on the international flow meter market.

Features

1) 0.5% of linearity;

2) 0.2% of repeatability;

3) Bilingual interface in Chinese and English;

4) 4 flow totalizers;

5) Patent balanced lower-voltage multi-pulse ultrasonic igniting;

6) built-in date totalizers;

7) work properly near transverters;

8) built-in data-logger;

9) 100 Pico-second resolution of time measurement;

10) 0.5 second totalizing period.

Principle of measurement

The ABDT-LCT-S ultrasonic flow meter is designed to measure the fluid velocity of liquid within a closed conduit. The transducers are a non-contacting, clamp-on type, which will provide benefits of non-fouling operation and easy installation.

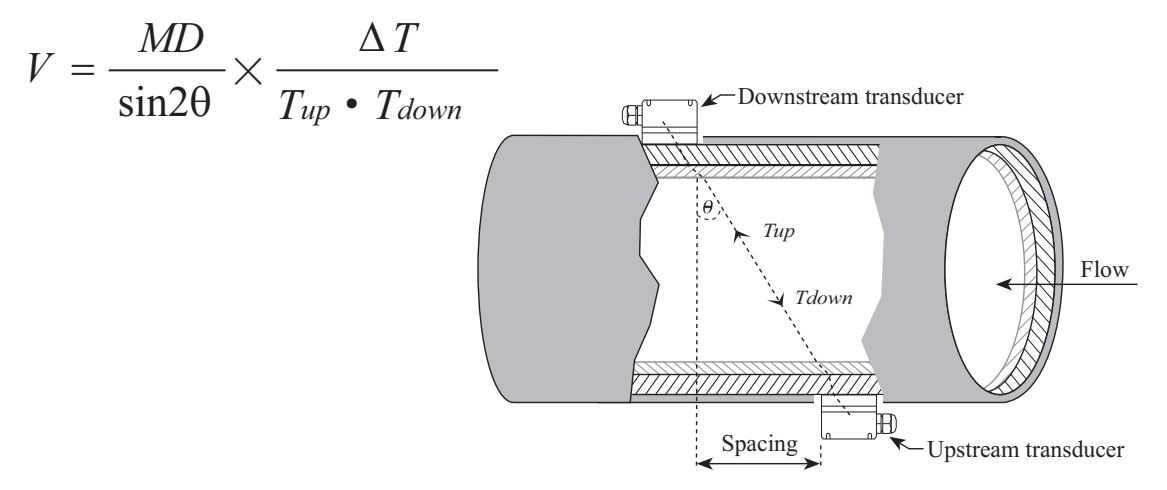

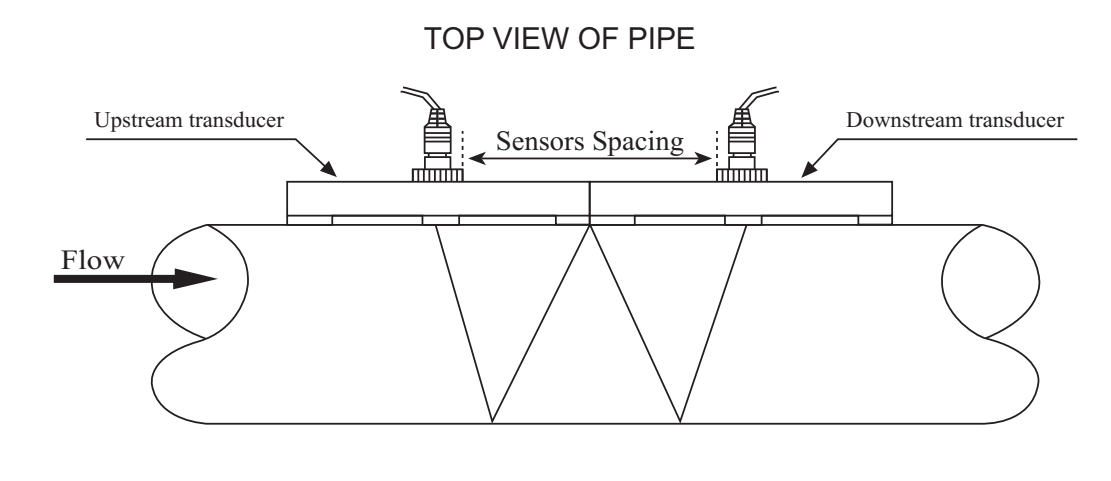

The ABDT-LCT-S transit time flow meter utilizes two transducers that function as both ultrasonic transmitters and receivers. The transducers are clamped on the outside ofa closed pipe at a specific distance from each other. The transducers can be mounted in V-method where the sound transverses the pipe twice, or w-method where the sound transverses the pipe four times, or in Z-method where the transducers are mounted on opposite sides ofthe pipe and the sound crosses the pipe once. This selection ofthe mounting method depends on pipe and liquid characteristics. The flow meter operates by alternately transmitting and receiving a frequency modulated burst of sound energy between the two transducers and measuring the transit time that it takes for sound to travel between the two transducers. The difference in the transit time measured is directly and exactly related to the velocity ofthe liquid in the pipe, as shown in Figure 1.

Where

θ is the include angle to the flow direction;

M is the travel times ofthe ultrasonic beam;

D is the pipe diameter;

Tup is the time for the beam from upstream transducer to the downstream one;

Tdown is the time for the beam from downstream transducer to the upstream one;

![]() T=Tup - Tdown.

T=Tup - Tdown.

Typical Applications

The ABDT-LCT-S flow meter can be virtually applied to a wide range of measurements. The measured pipe ranges 20-6000 mm [0.5 - 200 inch]. A variety of liquid applications can be accommodated: ultra-pure liquids, potable water, chemicals, raw sewage, reclaimed water, cooling water, river water, plant effluent, etc. Because the instrument and transducers are non-contacting and have no moving parts, the flow meter can not be affected by system pressure, fouling or wear. Standard transducers are rated to 110 ℃. Higher temperatures can be accommodated. For further information, please consult the manufacturer for assistance.

Specificatons

Linearity | 0.5% |

Repeatability | 0.2% |

Accuracy | ±1% of reading at rates>0.2 mps |

Response Time | 0.999 seconds, user-configurable |

Velocity | ±32 m/s |

Pipe Size | 20mm-6000mm |

Rate Units | Meter, Feet, Cubic Meter, Liter, Cubic Feet, USA Gallon, lmperial Gallon, Oil Barrel, USA Liquid Barrel, lmperial Liquid Barrel, Million USA Gallons. User configurable. |

Totalizer | 7-digit totals for net, positive and negative flow respectively |

Liquid Types | Virtually all liquids |

Security | Setup values Modification Lockout. Access code needs unlocking |

Display | 4x8 Chinese characters or 4x16 English letters |

Communication lnterface | RS-232C, baud.rate: from 75 to 57600. Protocol made by the manufacturer and compatible with that of the FUJl ultrasonic flow meter. User protocols can be made on enquiry. |

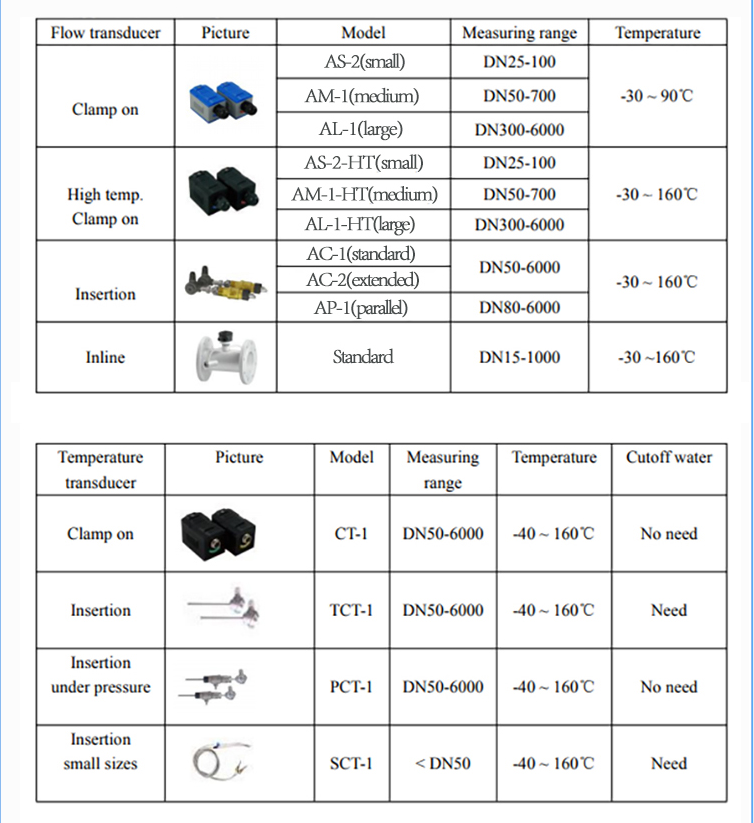

Transducers | Model M2 for standard, other 4 models for optional |

Transducer Cord Length | Standard 2x5 meters, optional 2x10 meters12x15 meters |

Power Supply | 3 AAA Ni-H built-in batteries. when fully recharged it will last over 10 hours of operation. 100V-240VAC for the charger |

Data Logger | Built-in data logger can store over 2000 lines of data |

Manual Totalizer | 7-digit press-key-to-go totalizer for calibration |

Housing Material | ABS |

Case Size | 100x66x20mm |

Handset weight | 514g (1.2 lbs) with batteries |

Installation method

Installation method of external clamp sensor

There are three types of external clip sensors available:

First, clean the area where the sensor is to be installed (it is better to use an angle grinder), remove the rust and rust proof layer, apply sufficient couplant on the pipe wall where the sensor is to be installed, and then attach and bind the sensor tightly. Note that there is no bubble or grit between the sensor and the pipe wall.

Installation distance

The distance between the innermost edges of the two sensors shall prevail (M25 window, see the installation diagram).

Installation method

There are four installation methods for external clip type sensors. They are V method, Z method, N method and W method.

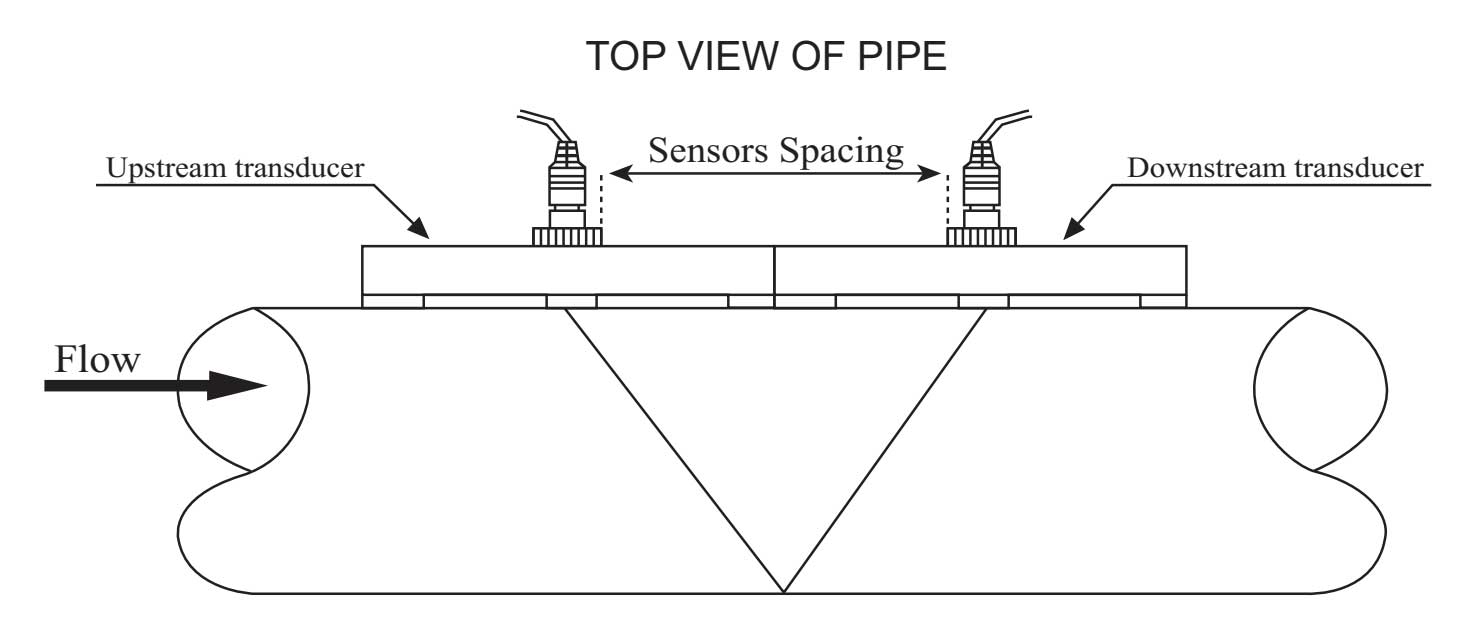

V method (applicable to the range of DN15-DN200mm)

V method is a relatively standard installation method, which is easy to use and accurate in measurement. During installation, the two sensors are horizontally aligned, and the center line is horizontal with the pipeline axis.

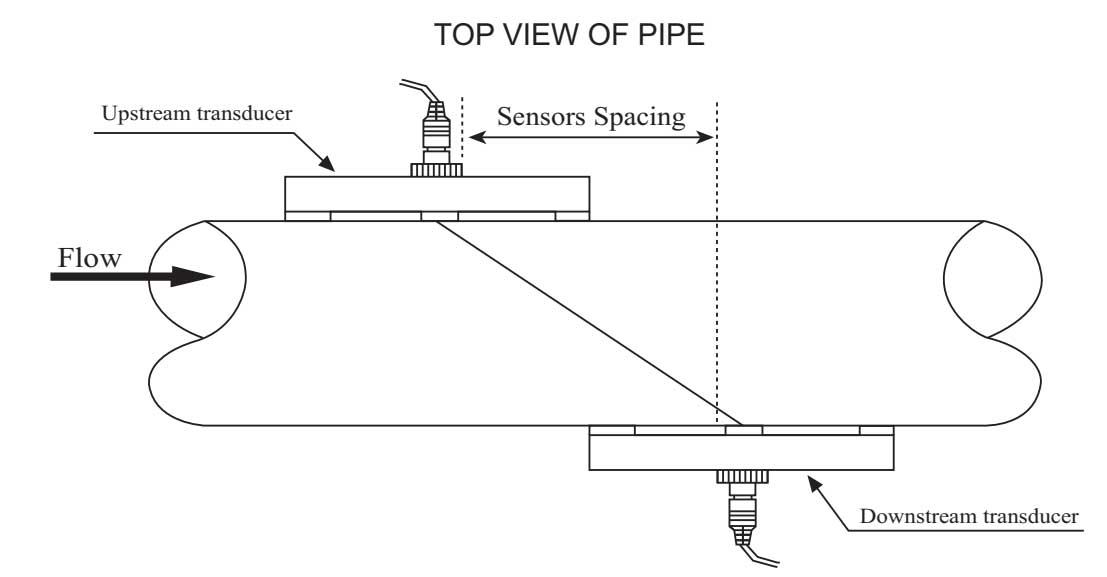

Z method (applicable to the case where the signal is above DN200mm or V method cannot measure or the signal quality is poor) is characterized by direct transmission of ultrasonic wave in the pipeline, no reflection (called single path) and small signal attenuation.

W-method is usually used on plastic pipes with a diameter from 10 millimeters to 100 millimeters.

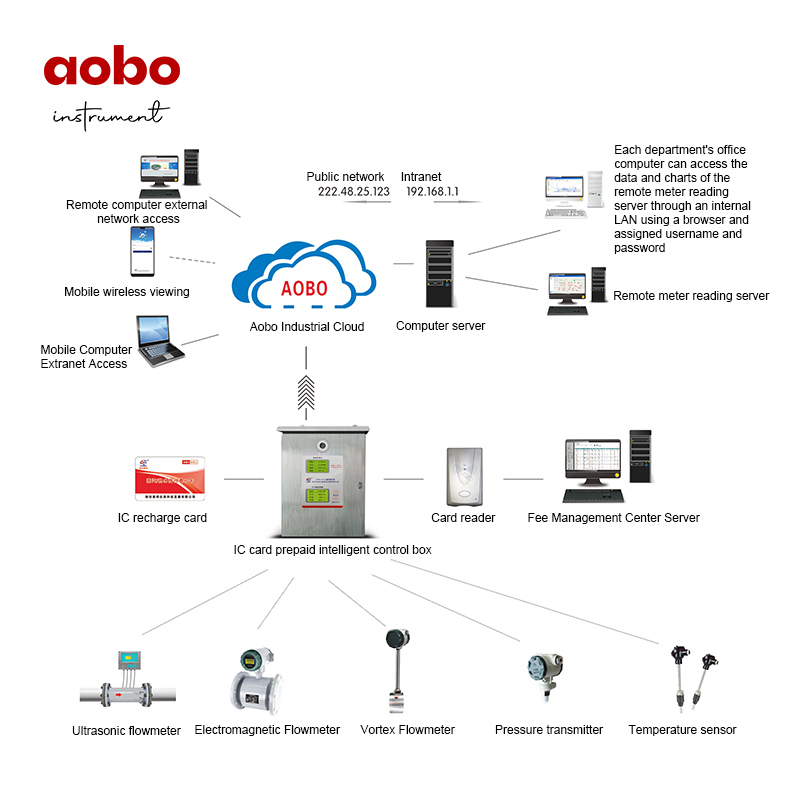

Steam/Hot Water IC Card Prepaid Intelligent Control System

In order to avoid billing disputes between energy supply and demand parties, reduce conflicts, and enable energy consuming units to consume clearly, Weifang Aobo Instrument independently developed and produced an IC card prepayment intelligent measurement and control system in 2008 that integrates early warning, anti-theft, and battery life functions, achieving a "payment before consumption" mode, completely solving the problems of difficult charging, meter reading, and management in thermal pow

View Products

Vortex Flowmeter

Vortex flow meters are mainly used for measuring the flow rate of pipeline medium fluids, such as gases, liquids, steam, and other media. When measuring the volumetric flow rate under operating conditions, they are almost unaffected by parameters such as fluid density, pressure, temperature, and viscosity. The vortex flowmeter adopts a piezoelectric stress sensor with high reliability and long service life, and can operate within the operating temperature range of (-20-350) ℃. There are analog

View Products

ultrasonic flowmeter

The LCT ultrasonic flow meter uses the time difference method to calculate the flow rate, and utilizes advanced micro processing digital technology. It is particularly suitable for measuring the flow rate of liquids such as regional heating, heat source plants, heat exchange stations, HVAC (air conditioning and refrigeration equipment), and tap water. The flow converter adopts a high-speed mixed signal processing CPU, equipped with a high-precision time measurement system that reaches 1ps, and h

View Products

Electromagnetic Flowmeter

The ABDT-LD series intelligent electromagnetic flowmeter is a relatively mature liquid measurement instrument, suitable for measuring the volume flow rate of conductive liquids (conductivity ≥ 5 µ s/cm) and slurries in closed pipelines. It is suitable for various acid, alkali, salt solutions, clean water, seawater, sewage, mud, pulp, mineral pulp, low conductivity liquids, etc. Widely used in industrial production process control, energy metering, environmental protection, sewage treatment an

View Products