News information

Location:Home - News - Company News

Key points for installation of electromagnetic flow meters

2022-08-01

Installation points

A. The installation site should not have large vibration sources, and reinforcement measures should be taken to stabilize the pipelines near the instruments;

B. Cannot be installed near large transformers, motors, pumps, and other equipment that generate large magnetic fields to avoid interference from electromagnetic fields;

C. The sensor should be connected to the pipeline to ensure full pipe operation, preferably installed vertically;

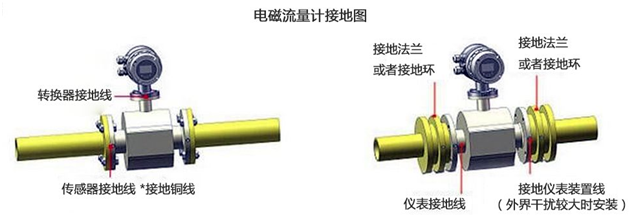

D. The transmitter casing can be grounded and connected to the nearby grounding grid; Shielded cables (split type) shall be connected according to the instructions, and signal cables (to the system) shall be grounded at a single end at the shielding layer system; The short circuit ring connecting the measurement sensor to the pipeline needs to be grounded, with a grounding resistance of less than 10 ohms and cannot be shared with electrical grounding;

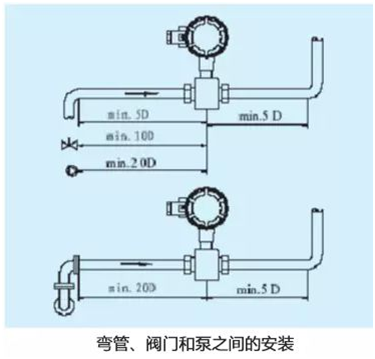

E. There should also be a certain straight pipe section upstream of the flowmeter sensor, usually between 5D and 10D.

Installation Details

If there is a steady-state eddy current in the measurement area, it will affect the stability and accuracy of the measurement. At this point, the length of the front and rear straight pipe sections can be increased, a flow stabilizer can be used, or the cross-section of the measurement point can be reduced to stabilize the flow velocity distribution.

The flowmeter can be installed horizontally and vertically, but it should be ensured to avoid the influence of sediment and bubbles on the measuring electrode, and it is better to keep the electrode axis horizontal. When installed vertically, the fluid should flow from bottom to top.

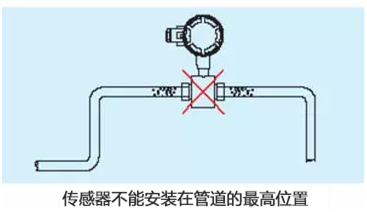

The sensor cannot be installed at the highest position of the pipeline, which is prone to the accumulation of bubbles.

Ensure that the flow sensor is filled with the measured fluid in the pipeline during measurement, and there should be no non full pipeline state.

If the pipeline is not full or the outlet is empty, the sensor should be installed on a siphon pipe.

The conventional straight pipe section requirements for electromagnetic flow meters are the first 10D and then 5D, with different requirements in the case of bends and valves.

Grounding reasons

The measuring electrode in an electromagnetic flowmeter is located in a DC or AC electric field, and if its environment cannot be effectively shielded under non-interference conditions, it will cause serious interference to the measurement. The grounding of the sensor casing directly affects the accuracy and stability of measurement. The grounding wire must not transmit any interference voltage. Therefore, electromagnetic flow meters require a very reliable grounding, and grounding shielding should be done to avoid interference current. Grounding benefits: If the pipeline connecting the flowmeter is insulated (relative to the measured medium), a grounding ring should be used, and its material should be selected based on the corrosiveness of the measured medium. If it is a measuring sensor lined with polytetrafluoroethylene, in order to ensure the normal operation of the measuring sensor, a grounding ring should be selected.