Solution

Location:Home - Solution

Solutions for the Paper Printing and Dyeing Industry

With the continuous improvement of national requirements for wastewater treatment in the papermaking, printing and dyeing industries, the accuracy of process control is becoming increasingly important. As the main instrument for process control, the stability, accuracy, and reliability of flow meters have become the main factors considered by papermaking and dyeing enterprises in the face of complex and ever-changing production processes.

In process control, flow meters are mainly used to measure the flow of process media, output (4-20) mA standard current signals, and upload them to DCS or PLC control systems, providing accurate, reliable, and fast regulation information for smooth production. The performance of flow instruments affects the stable operation of the entire production process, and the selection of instruments is crucial.

1. High accuracy, good repeatability, and fast dynamic response speed are required for flow meters.

2. There are various types of tested media, including steam, water, various acids, alkalis, salt solutions, organic solvents, etc;

The physical and chemical properties of the medium are different, and the reasonable selection of flow meters is very important.

3. The installation location and environment requirements for instruments are quite strict, with short straight pipe sections.

【Solution】

In the process of selecting flow instruments, based on production requirements and actual situations, the safety, accuracy, and economy of measurement are comprehensively considered, and the type and specifications of flow instruments are determined based on the properties and flow conditions of the measured medium.

Grasp two basic principles:

1. Ensure stable instrument performance, smooth process, and ensure production safety;

2. Ensure that the instrument accuracy meets the usage requirements;

Determine necessary selection parameters:

1. Determine the name of the medium, its acidity, alkalinity, and corrosiveness;

2. The upper and lower limits of flow during the production process;

3. Determine the upper and lower pressure values, temperature upper and lower limits in the measured medium pipeline;

4. Determine the size and material of the pipeline diameter;

5. Determine the on-site installation environment, power supply and other parameters.

The measurement of steam adopts AOBO-LUGB vortex flowmeter;

AOBO-LD electromagnetic flowmeter is selected for the measurement of conductive liquids;

For the measurement of non-conductive liquids, AOBO-LCT dual channel ultrasonic flowmeter is selected for large caliber; Small diameter rotor flowmeter is selected.

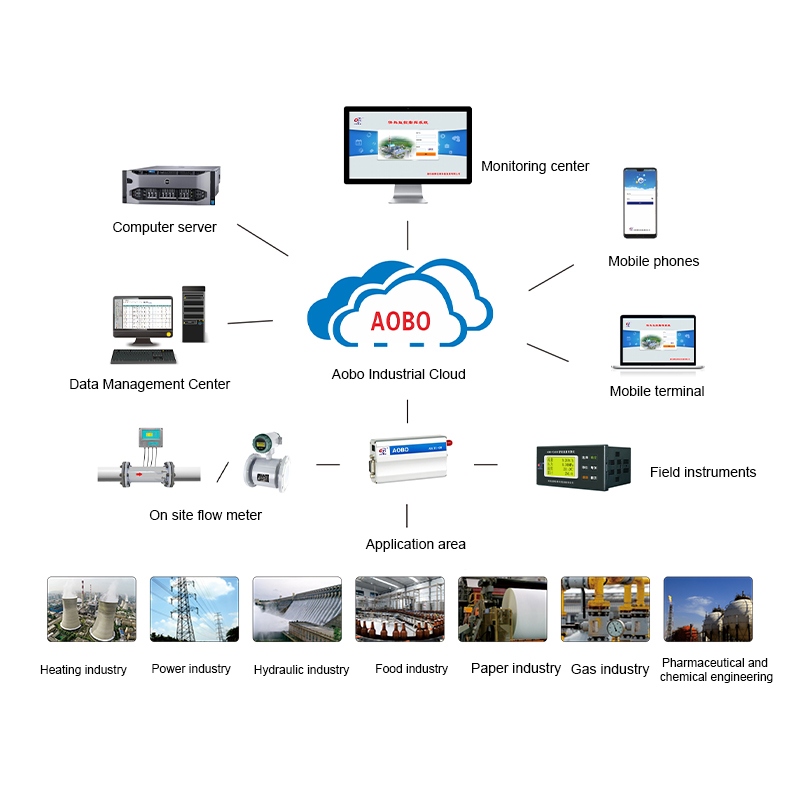

The assessment instruments of each branch or factory, including domestic water, production water, electricity, steam, sewage, and other instruments, are uploaded to the remote meter reading platform of the headquarters through communication for real-time monitoring and management. The GPRS remote meter reading system independently developed and produced by our company is selected.

In the process of selecting flow instruments, based on production requirements and actual situations, the safety, accuracy, and economy of measurement are comprehensively considered, and the type and specifications of flow instruments are determined based on the properties and flow conditions of the measured medium.

Grasp two basic principles:

1. Ensure stable instrument performance, smooth process, and ensure production safety;

2. Ensure that the instrument accuracy meets the usage requirements;

Determine necessary selection parameters:

1. Determine the name of the medium, its acidity, alkalinity, and corrosiveness;

2. The upper and lower limits of flow during the production process;

3. Determine the upper and lower pressure values, temperature upper and lower limits in the measured medium pipeline;

4. Determine the size and material of the pipeline diameter;

5. Determine the on-site installation environment, power supply and other parameters.

The measurement of steam adopts AOBO-LUGB vortex flowmeter;

AOBO-LD electromagnetic flowmeter is selected for the measurement of conductive liquids;

For the measurement of non-conductive liquids, AOBO-LCT dual channel ultrasonic flowmeter is selected for large caliber; Small diameter rotor flowmeter is selected.

The assessment instruments of each branch or factory, including domestic water, production water, electricity, steam, sewage, and other instruments, are uploaded to the remote meter reading platform of the headquarters through communication for real-time monitoring and management. The GPRS remote meter reading system independently developed and produced by our company is selected.