Solution

Location:Home - Solution

Solutions for the Food and Pharmaceutical Industry

In recent years, the frequent occurrence of food and drug safety issues has led to increasing quality requirements for food and drugs, and production process control is becoming increasingly important. As the main instrument for process control, flow measurement instruments are required to have sufficient contact with materials for a long time. The flow meter is not only economical and reasonable, but also meets the universal requirements of instrument stability, reliability, accuracy, and hygiene and safety; Provide strong guarantees for food and drug production.

In process control, flow meters are mainly used to measure the flow of process media, output (4-20) mA standard current signals, and upload them to DCS or PLC control systems.

There are various types of tested media, including steam, water, various acids, alkalis, salt solutions, organic solvents, etc; The physical and chemical properties of the medium also vary; The on-site working environment can vary from high temperature, high pressure, flammability, to explosiveness. The correct measurement of flow rate is an important means of production process control, playing an important role in ensuring quality, improving production efficiency, and ensuring production safety. This determines that the selection of on-site flow instruments is crucial.

Unlike general enterprises, the food and drug industry has special requirements for flow meters:

1. Any slight deviation in the amount of raw materials used will result in unqualified products, requiring high instrument accuracy and fast response speed;

2. Ensure production safety;

3. All component materials in contact with the medium comply with food hygiene requirements.

【Solution】

In the process of selecting flow instruments, based on production requirements and actual situations, the safety, accuracy, and economy of measurement are comprehensively considered, and the type and specifications of flow instruments are determined based on the properties and flow conditions of the measured medium.

Grasp three basic principles:

1. Ensure stable instrument performance, smooth process, and ensure production safety;

2. Ensure that the instrument accuracy meets the usage requirements;

3. Ensure that the instrument meets food grade standards;

Determination of selection parameters:

1. Determine the name of the medium, its acidity, alkalinity, and corrosiveness;

2. The upper and lower limits of flow during the production process;

3. Determine the upper and lower pressure values, temperature upper and lower limits in the measured medium pipeline;

4. Determine the size and material of the pipeline diameter;

5. Determine the on-site installation environment, power supply and other parameters.

The measurement of steam adopts AOBO-LUGB vortex flowmeter;

The measurement of conductive liquid adopts AOBO-LD stainless steel electromagnetic flowmeter;

For the measurement of non-conductive liquids, AOBO-LCT stainless steel dual channel ultrasonic flowmeter is selected for large caliber; Small diameter stainless steel rotor flowmeter or stainless steel liquid turbine flowmeter shall be selected.

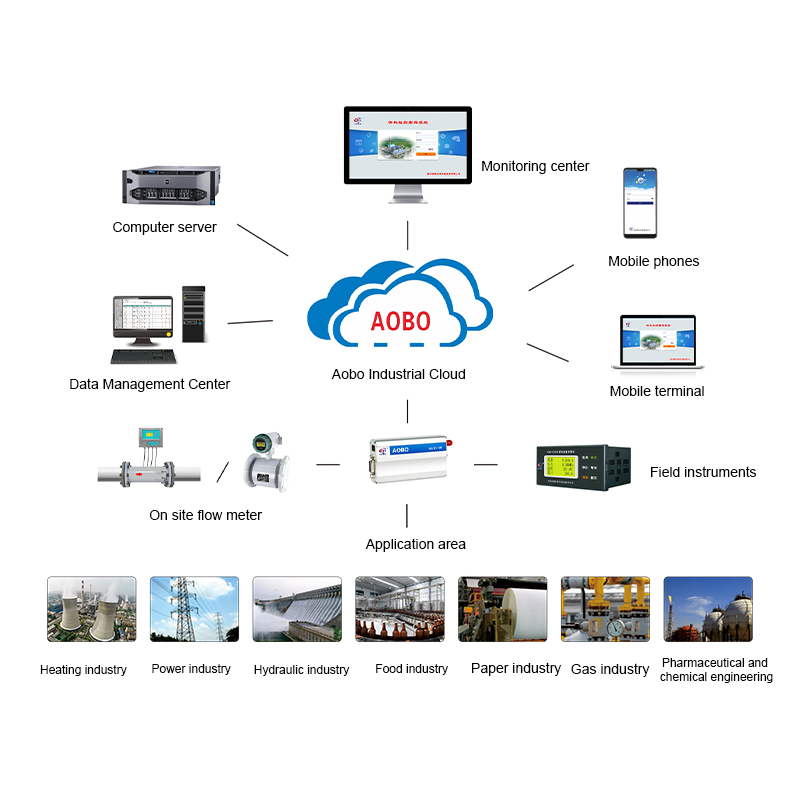

The assessment instruments of each branch or factory, including domestic water, production water, electricity, steam, sewage, and other instruments, are uploaded to the remote meter reading platform of the headquarters through communication for real-time monitoring and management. The GPRS remote meter reading system independently developed and produced by our company is selected.